We provide comprehensive control system solutions for machine tool truss standard manipulators, non-standard manipulators, and robot loading and unloading workstations, with application scenarios including: one drag one single machine, one drag three, two drag two, robot workstations, etc. Through professional robotic arm motion control algorithms, the product has excellent performance in high-speed and high-precision applications, convenient and easy to operate teaching, and a simple and intuitive graphical operation interface to meet the needs of casual control. The product has the function of monitoring the production and manufacturing Internet of Things, thereby improving production efficiency and quality.

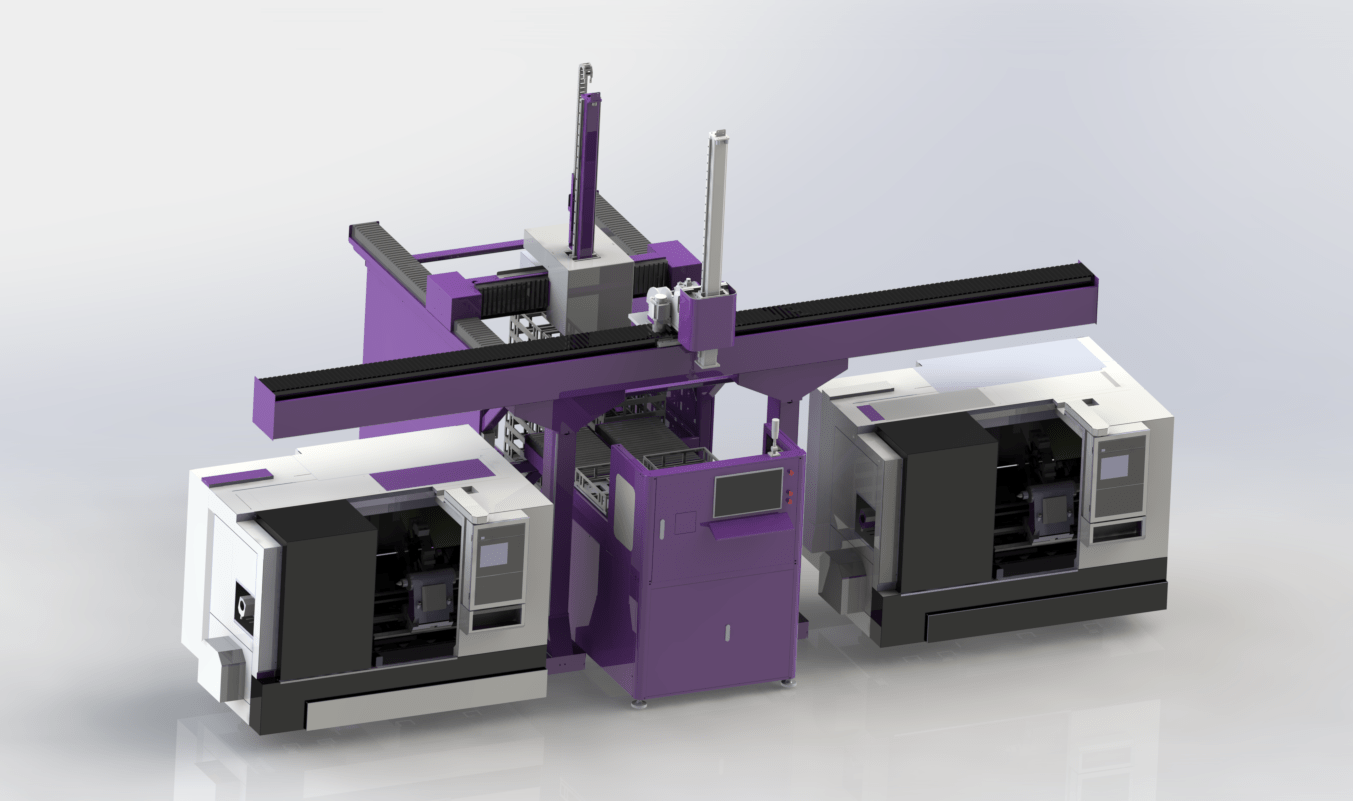

The control system is applied to the loading and unloading process of CNC lathes. One robotic arm carries three lathes for loading and unloading,effectively improving the quality and output of the factory. Chain silos, belts, dot matrix, lifting and other silos can be set up, which is convenient, flexible, high-speed, and high-precision. Advantages: Flexible and easy to understand, strong compatibility, high-speed safety, and strong anti-interference

More >

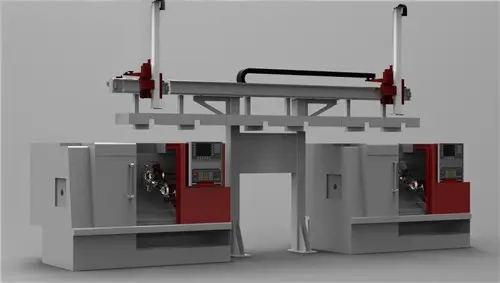

Applied to the loading and unloading process of CNC lathes, two CNC machines with one robotic arm effectively improve the quality and output of the factory. It can be equipped with chain silos, belts, lattice, lifting and other silos, which is convenient, flexible, high-speed, and high-precision. Advantages: flexible and easy to understand, strong compatibility, high-speed safety, and strong anti-interference

More >

Applied in the keyboard industry, after taking out pressure assembly and injection molding, place tooling and fixtures for assembly,detect defective products, place them aside, and place the finished products on the conveyor belt. Advantages: reduced manual assembly, high-speed safety, and strong anti-interference

More >

Applied to the loading and unloading process of CNC lathes, one CNC with one robotic arm effectively improves the quality and output of the factory.It can be equipped with chain silos, belts, lattice, lifting and other silos, making it convenient, flexible, high-speed, and high-precision. Advantages: Flexible and easy to understand, strong compatibility, high-speed safety, and strong anti-interference.

More >

The Application of LAVICHIP CLACT306 Bus Manipulator Control System on Double Z-axis (Two Dragged Two) Truss Manipulator 1. Case background: Truss type robotic arms are widely used in automated production lines, such as CNC CNC lathes and CNC machining centers. They automatically complete loading and unloading of materials for processing, thereby reducing labor costs, improving production efficiency and quality. The dual Z-axis (two dragged two) truss manipulator has high requirements for control system algorithms and technology, ensuring that the mechanical arms operate independently and do not interfere with each other. Due to the need for more complex processing with multiple machine tools, it is oftennot possible to use an independent single arm robotic arm. It is necessary to coordinate and work in parallel with multiple arms to complete up and down material retrieval, thereby saving hardware costs and meeting real-time process requirements. 2. Technical difficulties (for a certain process): A: Lathe loading and unloading process, applied to small lathes to pick and place processed workpieces, replacing manual automation B: The conveyor belt silo is layered with partitions, achieving automatic retrieval and placement of three-dimensional silos, reducing customer complexity in silo tooling design, and equipped with stacking technology, C: Standard stacking, one group for material retrieval, two groups for material placement, three groups for partition separation between subroutines,and four groups for finished product partition separation. After completing one building, use subroutines to feed the entire pile and stop after sensing in place.

More >Copyright © Shenzhen Lavichip technology co.,Ltd. |